Found Money: How to Clean Up Preference Cards to Cut Inventory Spend (2 of 3)

August 19, 2016 Topics: HealthcareThis three-part series examines the potential for hospitals to capture inventory savings through more efficient management of physician preference cards.

In the previous post, we identified inaccurate physician preference cards as the main culprit in poor inventory management in hospitals, leading to inefficiency and wasted spend. Now, we will outline the actions hospitals should take to identify their losses and capture the potential savings available by cleaning up their existing preference cards.

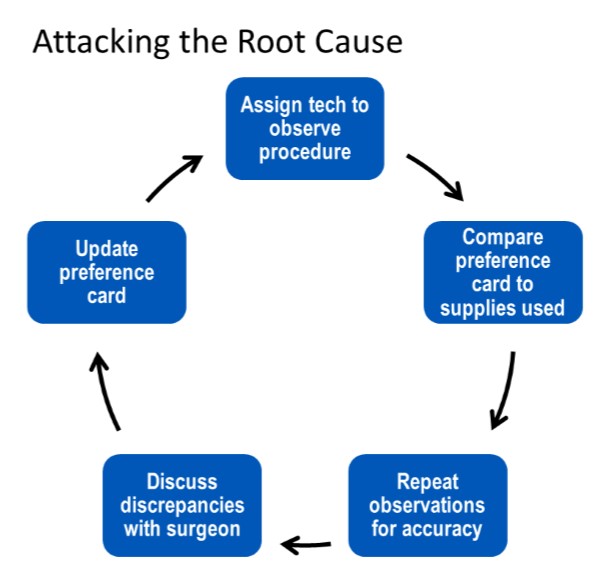

Part 2 – Attacking the Root Cause

How can hospitals identify what they are actually losing due to inaccurate preference cards—and, more important, actually capture those potential savings? They need to start by attacking the root of the problem and clean up their existing preference cards.

This typically begins with focusing on a particular service (e.g., orthopedics) and all the doctors who perform surgery within that service. To understand how accurate those doctors’ preference cards really are, the hospital should appoint a team to get an on-the-ground look at each doctor’s use of routine medical surgical supplies during surgery. The team typically comprises an onsite program manager as well as several sterile techs who are responsible for observing the procedures. The number of techs on the team varies by the number of surgical procedures targeted. As a general rule, two techs are needed for every 15,000 annual procedures.

At the end of each procedure, the techs document what was used, what was unused and unopened and what was opened and discarded. They then compare this snapshot with the associated preference card to identify how closely actual supply use during the procedure matched what’s on the preference card.

To ensure the data gathered are representative and accurate, a tech repeats this process four more times for the same doctor and procedure.

With these data in hand, the techs can have a fact-based discussion with each doctor to illustrate the disparity between his actual supply use across the five observed surgeries and what’s on his preference card. This includes pointing out items on the card the doctor used and frequency of use (e.g., 100 percent, 80 percent and 50 percent of the time); those on the card he never used; and those he used (and how frequently) but weren’t on the card—i.e., the ones the nurse had to rush out to retrieve in the middle of surgery.

The goal of this discussion is to give the doctor the data necessary to make an informed decision about which items should remain on his card or be added to it, and which should be removed, so that it accurately reflects his actual use. Once the doctors provide their input on what their cards should now contain, the techs make the requested changes to each doctor’s preference card in the OR IT system.

The techs also give the updated cards to procurement professionals so they can make better-informed decisions about what they should order. This, in turn, ensures inventory better reflects what’s actually being used in the OR. For instance, procurement may find that a certain doctor no longer uses a particular item, or less of it than he once did, and can recalibrate purchasing accordingly. Doing so can go a long way toward putting the clamps on inventory bloat.

In the final section of the series we will discuss how hospitals can maintain and sustain the benefits they receive from cleaning up their preference cards.

Read the next post in this series.

Read the previous post in this series.

Sedlak Management Consultants is an industry leader in supply chain strategy and inventory planning, with a specialize practice in healthcare. From manufacturers to distributors to providers, we help poise healthcare companies to manage continual changes brought on by regulation, mergers and acquisitions, and ever-changing product mixes.

If there is any way we can support your healthcare supply chain or distribution optimization, please feel free to contact us by filling out the form below.